Background

___

Water treatment facilities are designed for long-term operation in demanding and often harsh environments, typically with a lifespan of more than 50 years. Traditionally, water treatment plants (WTPs) and wastewater treatment plants (WWTPs) have operated with two process control and maintenance (PC&M) strategies:

-

Experience-guided PC&M, which relies heavily on operator's experience and historical practices or knowledge developed through laboratory/pilot studies.

-

Reactive PC&M, where adjustments of control parameters or maintenance is only performed when significant process deviations resulting from system failure have occurred.

As is the case with other physical assets, WTPs and WWTPs inevitably experience performance degradation. Moreover, WTPs and WWTPs always operate under dynamic conditions caused by seasonal and daily fluctuations in raw water characteristics (e.g., temperature and organic loading), varying demand for treatment capacity and treated water quality, and many other factors. Both conventional PC&M strategies may hence lead to inefficient operations and additional operating costs caused by the difficulties in adapting to constant changing operating conditions in real time, potential mismatches between experimental conditions and full-scale operating conditions, and the risk of unplanned downtime and repairs. Therefore, the implementation of proactive PC&M in response to changing conditions or predicted failures is crucial to ensure resource-efficient and, potentially in the long term, carbon-neutral operation of water treatment facilities. Specifically, proactive process control requires the continuous monitoring and adjustment of process parameters to maintain optimal performance under varying conditions, while proactive maintenance involves condition-based predictions to anticipate equipment degradation and schedule maintenance activities in advance.

Competitive advantages

___

The CTET team has developed and deployed ML-enabled DTs from present-centric SCADA for real-time monitoring, through short-term predictive CPS for adaptive control and limited proactive PC&M that can deliver real-time system assessments, forecasting and proactive PC&M.

Applications

___

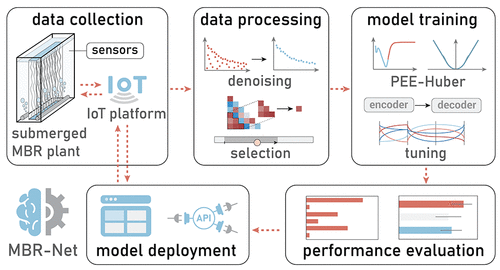

Machine learning-enabled digital twin assists intelligent operation and maintenance of membrane bioreactor (MBR) wastewater treatment plants

With the machine learning-driven digital twin technology (ML-DT) developed by CTET, MBR plants for municipal wastewater treatment can achieve intelligent process control and maintenance (PC&M), significantly improving operational efficiency and sustainability.

- By dynamically adjusting dissolved oxygen levels, the system effectively reduces energy consumption, supporting green and low-carbon operations

- Leveraging accurate predictions of membrane fouling trends under various operating conditions, it enables predictive maintenance, significantly reducing downtime risks and operational costs

This ML model offers the following innovations:

LSTM Encoder–Decoder Model Structure for Multihorizon Prediction

We used an encoder–decoder or sequence-to-sequence (Seq2Seq) structure for the process of heterogeneous past observed and known future sequential data to generate a multihorizon prediction of the target variable (i.e., permeability). The encoder consists of two layers of 900 LSTM cells, and the decoder consists of one layer of 180 LSTM cells, with each cell assigned to process the data at a specific time step in the past or in the future.

MBR Database

The dataset employed in this study was collected from two large-scale municipal wastewater treatment plants. It comprises minute-level data from a wide array of IoT sensors deployed across twelve independently operated membrane bioreactor (MBR) tanks/trains. These sensors monitored key operational parameters such as dissolved oxygen, transmembrane pressure, flow rates, and temperature, etc.

The time-series dataset used for model development and validation spans a total duration of two years, comprising over 365,000 individual data entries.

Custom Loss Function

To address the challenges of outliers and data imbalance in real-world sensor datasets, we developed a customized weighted Huber loss function, named polynomial-exponential-enhanced Huber (PEE-Huber) loss function. This function introduces adaptive weighting mechanisms to enhance sensitivity to rare but critical events, such as severe membrane fouling and post-cleaning recovery, which are typically underrepresented in conventional datasets.

Application programming interfaces (APIs) and architecture of the web application

A visualised web-based API was developed to enable real-time acquisition, denoising, and online prediction of historical operational data from the IoT data platform. This system is specifically designed to support intuitive interaction for operators at municipal wastewater treatment plants.

Through this interface, operators can accurately monitor and forecast membrane fouling conditions. This capability empowers them to make informed decisions regarding fouling mitigation strategies, addressing operational challenges with greater precision and responsiveness.